CNC Machining Service

How M2 CNC Machining Service Helps?

M2 Prototype offers a reliable and cost-effective CNC machining service that provides precision results and flexibility for all types of custom product design and fabrication needs. Our CNC machining capability can rapidly produce parts and components to exacting specifications, making it ideal for product development and prototyping, as well as small batch and fast mass production. With our state-of-the-art equipments and programming expertises, we can handle a wide range of CNC machining services, from a single prototype to thousands of parts. Our experienced engineers work closely with customers to identify their requirements and implement customized manufacturing solutions to meet their needs.

At M2 Prototype, we employ the latest in cutting-edge technology and strict quality control measures to ensure unparalleled accuracy and repeatability for our customers’ parts. Our CNC machines can produce parts with dimensional accuracy, fine surface finishes, and a variety of machining processes. We can create designs with intricate details, minimize tooling requirements, and reduce lead times while still delivering high-quality parts. Our CNC machining service also provides cost savings by reducing machining time and materials without compromising quality. Whether you need a complex design or custom product, our customized machining service is the perfect solution to meet your unique needs.

Need CNC Machining Service?

CNC Milling

CNC Milling is a highly accurate cutting operation often used to shape plastics, metals and other hard materials. We uses a high precision spindle to rapidly rotate a cutting tool to shape material according to the user’s programming specifications. The tool is then moved around the workpiece in the axis directions indicated in the program to createhigh-accuracy components.

Our CNC milling is a powerful and versatile manufacturing process that offers accuracy, high quality, and precision at a cost-efficient price. It can be used to create components in a range of sizes and shapes in a number of materials, and is the preferred process in industries ranging from aerospace to medical device production.

CNC Turning

CNC Turning is a computer-controlled machining process that is widely used to produce a wide range of parts with varying shapes, sizes, and complexities. We utilize a computer-operated lathe and a variety of cutting tools, lathes, and boring tools to remove material from a workpiece and create the desired shape. CNC turning is also ideal for producing irregularly shaped objects like screws, pins, and rods.

We utilize the latest CNC turning technology to provide our clients with a reliable and efficient machining service. Our CNC turning process is controlled by a computerized program that provides precise control over the machining process, ensuring that each part is manufactured to exacting tolerances. With this level of precision and accuracy, we can produce parts that meet the high standards required in industries such as aerospace, medical, and electronics.

3,4,5 Axis CNC Machining

M2 provides 3 axis CNC machining service to uses single rotating tool to cut away material from a stationary workpiece. it is best suited for parts with simple geometries, such as cylinders and rectangular blocks.

Our 4 axis CNC machining service adds an additional fourth rotational axis to the 3 axis process, allowing for the production of more complex parts with contours, bevels and grooves.

By adding another axis of rotation, our 5 axis CNC machining service enables the full rotation of a part to be machined in all planes. This advanced technology is capable of producing highly complex parts with complicated surfaces and 3D components.

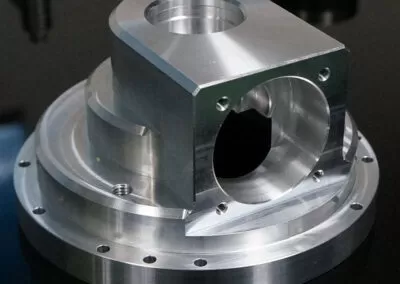

CNC Machining for Metal Parts

M2 Prototype offers customized metal part CNC machining service that provides precision-crafted components and sub-assemblies. The state-of-the-art facility in M2 houses a multitude of CNC machining centers, designed and programmed to our exacting standards to provide quick turnaround times, pristine quality, and cost-effective production. Programming team in M2 creates efficient code for the machines, which increases speed, accuracy and decreases machining time. Our team of highly-trained machinists, inspectors and engineers have over 20 years of experience in precision metal machining, and are on hand to provide consultation and technical support throughout the course of any project. All of our products are built to the highest standards.

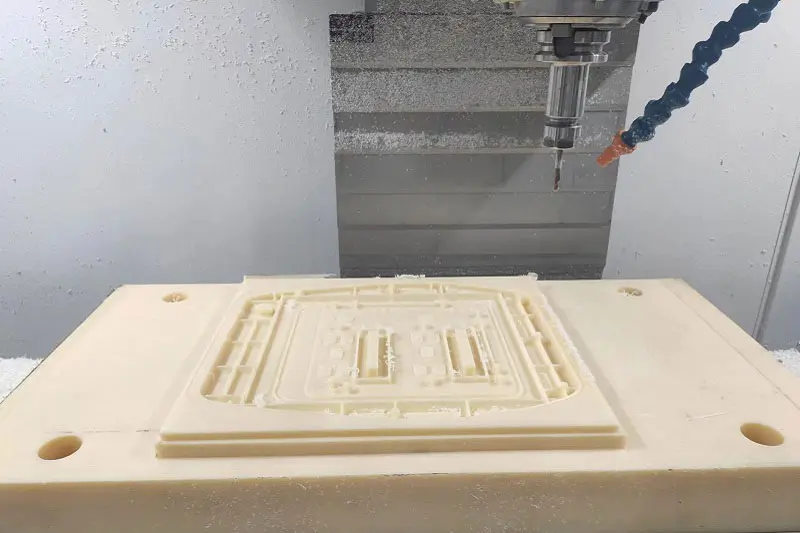

CNC Machining for Plastic Parts

M2 Prototype provides customized CNC machining services for plastic parts that are precise, reliable, and cost-effective. We have high-tech CNC machining centers that are designed and programmed to meet the most demanding specifications. Our programming team creates efficient and accurate codes for the machines, which helps to increase machining speed and reduce turnaround time. Our team of highly-trained machinists, inspectors, and engineers have extensive experience in precision plastic machining, and are available to provide technical support and consultation throughout the entire process. Whether you need a single prototype or a large production run, we have the expertise, technology and resources to meet your exact requirements.

Surface Finishing after CNC

Mechanical, chemical, and thermal surface finishing treatments are provided by M2 Prototype. Our mechanical treatments involve using grinding or polishing wheels, or abrasive media to finish the surface of the parts. We offer a range of mechanical treatments, including polishing, buffing, and brushing to achieve specific surface finishes. We also offer various chemical treatments, such as pickling and anodizing to achieve desired results. Our skilled technicians use different chemical processes to improve the parts’ surface quality, including enhancing corrosion resistance, improving wear resistance, and providing a decorative finish. Besides, we provide thermal treatments like heat treating and carburizing to modify the physical and mechanical properties of the materials.

CNC Machining FAQs

What is CNC machining?

CNC machining is a manufacturing process that utilizes computer numerical control technology to automate the production of parts. In CNC machining, computer aided design (CAD) models are used to generate instructions that are transmitted to a computer numerical control (CNC) machine, which in turn produces the finished part.

What type of materials can be used in CNC machining?

CNC machining can be used to produce precision parts from a variety of materials, including metals (e.g. aluminum, brass, stainless steel), plastics (e.g. ABS, nylon, polycarbonate), composites (e.g. carbon fiber, Kevlar), and wood.

Can CNC machining be used for complex geometries?

Yes, CNC machining is capable of producing highly complex parts with precise geometries. Thanks to the high accuracy of CNC machines and precise control over the cutting process, CNC machining is ideal for producing intricate parts with exact tolerances.

How long does it take to complete a CNC machined part?

The time it takes to complete a CNC machined part depends on the size of the part, the material being used, and the complexity of the geometry. Generally speaking, simple parts can be completed in a matter of hours, while more complex parts can take days or weeks to finish.

What are the limitations of CNC machining?

The main limitation of CNC machining is that it relies on rigid cutting tools and material removal. As such, it can be difficult to fabricate parts with highly complex shapes and internal geometries that require tight tolerances. A best alternative way is our 3d printing services for extremely complex parts.

What equipments do you run for cnc machining?

We run a variety of machines and equipments, including milling machines, lathes, CNC routers, press brakes, welding machines, grinders, drills, and CNC plasma cutters etc.

How are CNC machined parts inspected?

The level of inspection and quality control will depend on the customer’s requirements, but elements that are commonly inspected include geometry, surface finish, surface hardness, dimensional accuracy, and material properties.

How accurate are CNC machined parts?

CNC machined parts can be highly accurate and precise – typically, the average accuracy for most machines is within 0.005mm, though tolerance will depend on the type of machine being used.

Is CNC machining cost-effective?

CNC machining can be a cost-effective production method for many applications, especially when high volumes of parts are required. It is also possible to reduce costs by using a combination of machining, 3d printing and other additive techniques.

Does CNC machining require any special skills to use?

Yes, the successful execution of CNC machining requires specialized knowledge and experience. Operators must have a comprehensive understanding of the machining process, the material being used, and the necessary tools and techniques to ensure accuracy and precision. Our experienced engineer team will guarantee smooth cnc machining for your customized prototypes.

Is CNC machining environmentally friendly?

CNC machining can be environmentally friendly, as the process generates minimal waste and can userecycled materials. lt is also possible to employ green manufacturing techniques to further reduce theenvironmental impact of CNC machining.

Computer-Aided Design (CAD)

Creating a 3D model of the part or product that needs to be manufactured by drawing the design on computer-aided drawing software. This will provide engineers with a blueprint of the product and be used to program the cutting and shaping of the material.

Computer-Aided Manufacturing (CAM)

Using the created CAD design, specialized software is used to translate the design into a code of commands that a computer numerical control (CNC) machine can interpret, in order to create the component.

Preparing the CNC machine

The CNC machine is then prepared with the necessary tools, cutting speeds, and depth of the cuts. This setup is unique to the component, so it takes some time to ensure the programming and setup are properly adjusted.

Fixturing

This is the process of clamping down the component and setting up the machine to produce the component accurately. This process is also dependent on the component being made and can be quite complex and time consuming.

Machining and cutting

The CNC machine is then controlled by the program and begins to produce the component. The tool is run by a series of motors and moves the cutting tool along the desired paths on the component.

Finishing

Depending on the requirements of the job, this step may include various finishing processes such as chroming, anodizing, and polishing, brusning, powder coating.

Inspection

Once the component is cut, an inspection takes place to ensure that the component is up to the specifications. This process can be done manually or with the use of calibrated digital equipment.

Post-Processing

The finished parts are packed or labeled in order to be sent to the customer. This step may also include any post-processing steps that are needed in order to get the parts ready for shipping.